Why do we need sewage treatment plants?

- Landscaping.

- Irrigation.

- Makeup for cooling towers.

- Network flushing and cleaning.

- Recharge aquifers

- Reduce the salt content in particular groundwater.

- Industrial systems.

- Vehicle washing systems.

Reduce pollution

Maintain cleaner Environment

Save the cost of using potable water

Reuse of natural resources

Protect the health of public

What Are the technologies used to treat the sewage

Being one of the market players in the Gulf Region, specifically in Bahrain, Qatar, Kuwait, UAE, Iraq, Yamen, and KSA, We understand that each country has its regulation and limits for discharge; for that reason, we offer engineering custom-made plants designed to meet your requirement.

Space requirement is also one of the main challenges that our customers face, and we support them by offering different technologies that can be supplied as modular packages to fit the spaces allotted for the plants.

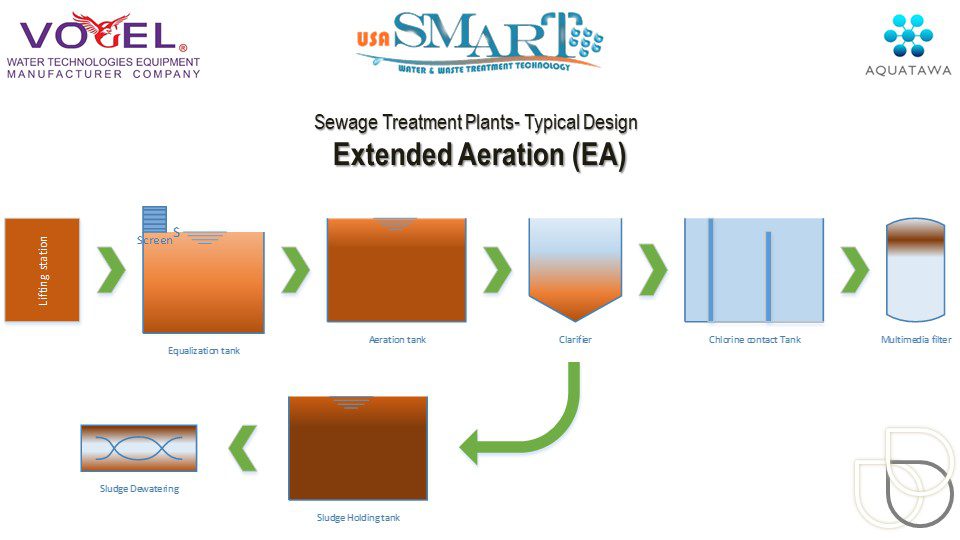

Extended Aeration (EA)

Extended aeration is typically used in prefabricated “package plants” to minimize design costs for waste disposal from small communities, tourist facilities, or schools.

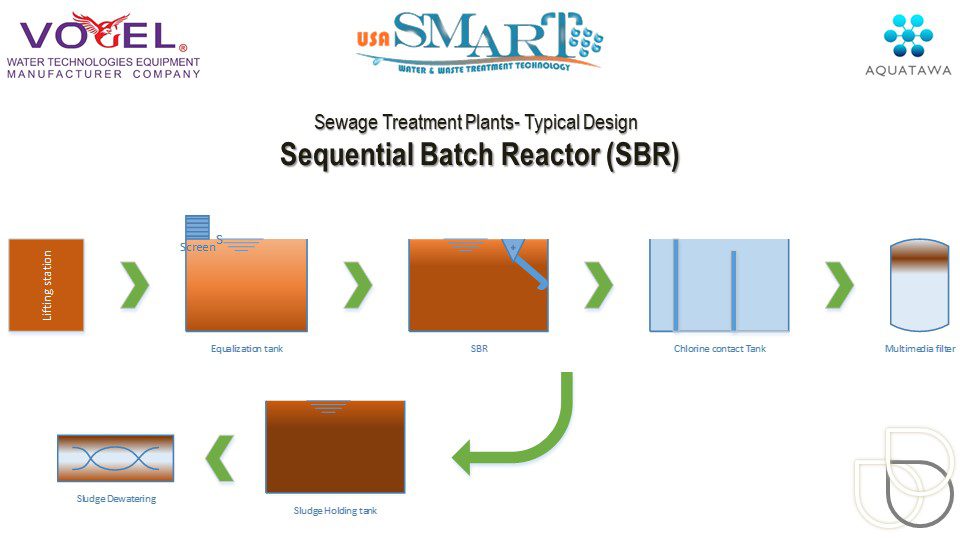

Sequential Batch Reactor (SBR)

A type of activated sludge process for the treatment of wastewater. SBR reactors treat wastewater in batches. SBR tank is utilized to serve several steps of the treatment, Filling, Reacting , Settling , Decanting, and desludging.

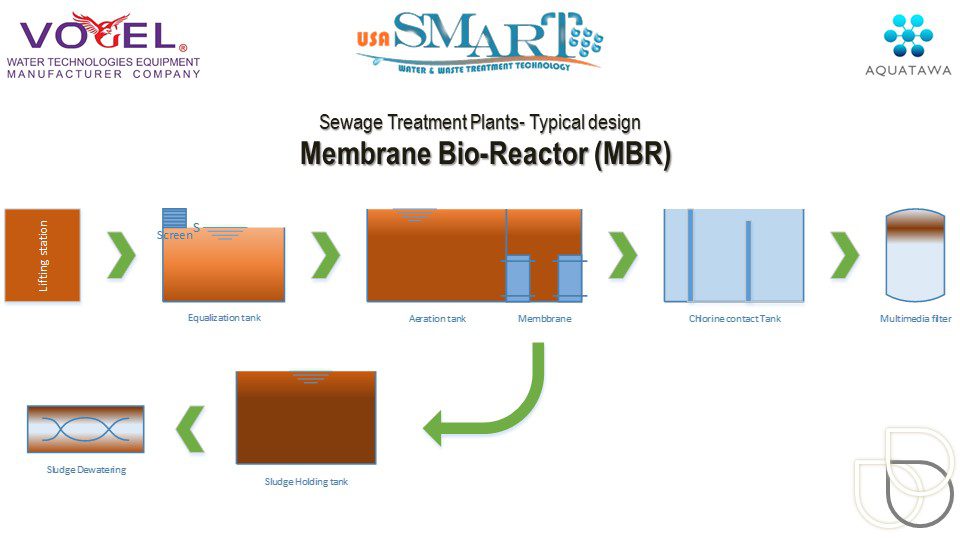

Membrane Bio Reactor (MBR)

They are utilizing membrane technology to separate the supernatant from mixed liquor. The MBR processes can produce high-quality effluent to be discharged to the coastal surface, brackish waterways, or reclaimed for urban irrigation. Other advantages of MBRs over conventional methods include a small footprint, easy retrofit, and upgrading old wastewater treatment plants.

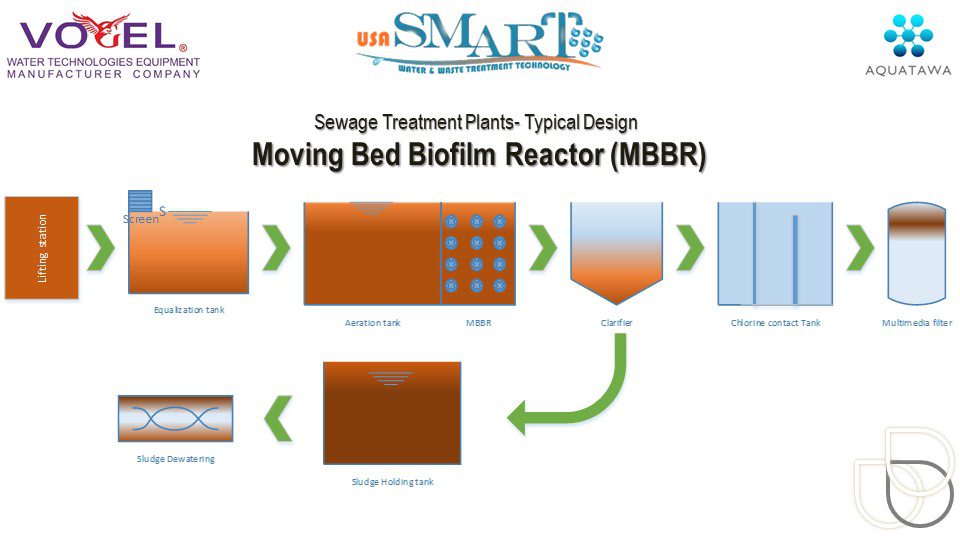

Moving Bid Biofilm Reactor (MBBR)

The MBBR system consists of an aeration tank (similar to an activated sludge tank) with special plastic carriers that provide a surface where a biofilm can grow.

The system provides a minimum footprint compared to other types of treatment.

Our customers

As a sewage treatment plant manufacturer and operating system, Smart Water Treatment Technology Group serves several business sectors in the Middle East, including design and build as well as operation and maintenance services specifically for those customers in Bahrain, Qatar, Kuwait, the UAE, KSA, and Egypt.

- Farms

- Industrial Waste

- Labor Camps

- Municipality

- Communities & residential area

- Consultancy firms

- Hotels and resorts

- Hospitals and Clinics